Testing the Elios 3 Surveying Payload at ICL Boulby Mine

Discover how the latest Surveying Payload transformed surveying operations at the underground mine ICL Boulby, completing surveys more efficiently than ever before.

Key Advantages

|

Better Data Coverage The Elios 3's upgraded LiDAR payload offers enhanced range, allowing it to cover larger areas with higher precision in the same amount of time compared to the standard setup. |

Faster Surveys With the Surveying Payload, data collection is quicker, and flight durations are reduced. For instance, a 340-meter-long tunnel was mapped in just 10 minutes at ICL Boulby. |

|

Simpler Flight Planning The new Rev 7 LiDAR makes flight planning easier due to its extended range and superior data coverage, cutting surveying times in half at ICL Boulby. |

Improved Accuracy The new payload reduces LiDAR drift by five times compared to the standard setup, ensuring greater accuracy even in complex environments. |

When Flyability tested the new Surveying Payload for the Elios 3, they chose a location already familiar with the Elios 3’s LiDAR data—ICL Boulby. A team from Flyability visited the site to compare the performance of the new Ouster Rev 7 LiDAR payload against the previous version.

Using the Elios 3 at the World's Only Polyhalite Mine, ICL Boulby

ICL Boulby is unique as the world's sole polyhalite mine, located just north of Whitby in Northeast England. Originally opened in 1968 to extract potash, it now focuses on polyhalite, an organic fertilizer. Operating at depths of up to 1,200 meters below ground, the mine stretches under the North Sea, extending up to 12 kilometers offshore.

Managing such a vast, historic site presents challenges, particularly with its labyrinth of old workings alongside ongoing excavations. Accurate mapping is essential to avoid accidents caused by hitting old workings, which could lead to gas or water influxes. Maintaining precise records is legally mandated in the UK.

Simon Pollitt from ICL Boulby suggested using the Elios 3 to map mine workings as part of their documentation process. Their mining method involves advancing into new areas while retreating from older ones, making the Elios 3 invaluable for staying compliant with safety regulations.

By 2023, the Elios 3 had been operational at ICL Boulby for nine months, and the surveying team relies heavily on its regular LiDAR scans for various surveying and volumetric projects.

Halving Drone Flight Times with the New Surveying Payload

A particular tunnel at ICL Boulby measured 340 meters long and previously required four flights with the Elios 3 to fully map it, taking 20 minutes in total. This involved flying beyond visual line of sight, complicating communication between the drone and the operator. Post-flight, scans were registered and processed to generate point clouds.

However, the introduction of the new LiDAR scanner made a significant impact.

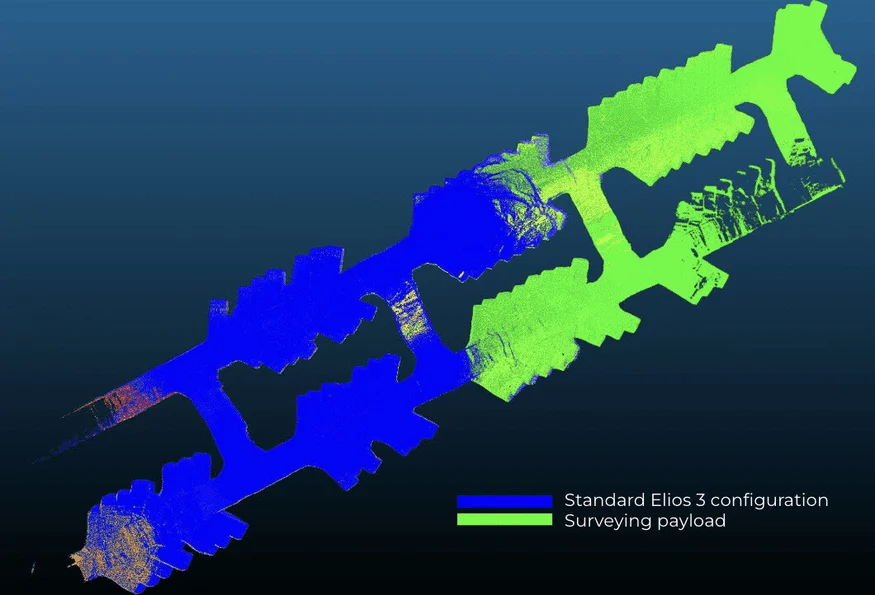

Twice the coverage: Overlays show double the coverage with the new Surveying Payload compared to the standard configuration.

The new Surveying Payload features an updated LiDAR sensor—the Ouster LiDAR OS0-128 Rev 7. This upgrade offers improved positioning accuracy, better performance in symmetrical settings, and extended range. As a result, denser and richer point clouds can be collected more efficiently and processed using FARO Connect software. This software automates the creation of clean, georeferenced point clouds from the Elios 3’s new payload.

VIDEO: Fly-through of the data captured in one flight by the Elios 3 Surveying Payload

With the new surveying payload, Simon completed the same survey in just one flight, halving the flight time and conserving battery power. Additionally, because of the increased range, post-processing time was reduced since fewer scans needed merging.

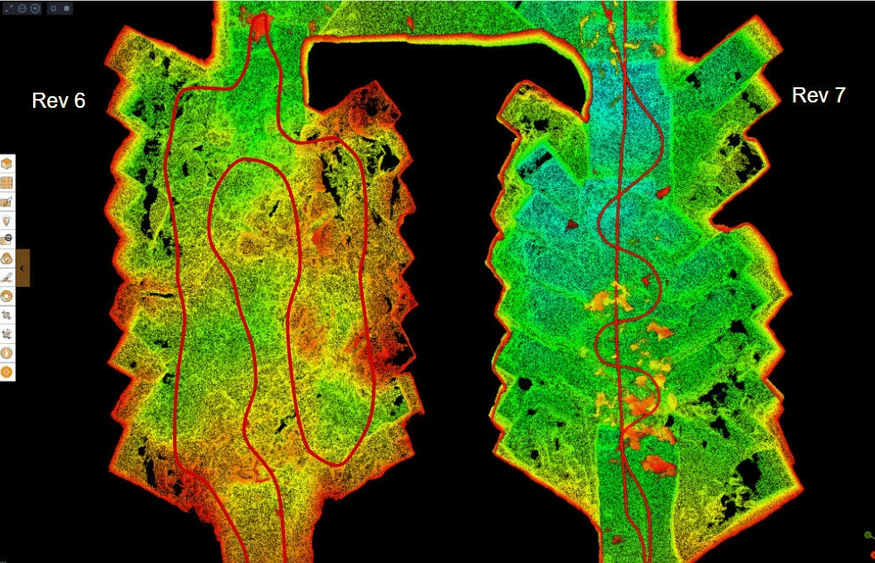

Simplified flight path: The left image shows the original payload's flight path, while the right image displays the new surveying payload's simplified trajectory.

Reduced Drift and Enhanced Z-Axis Precision

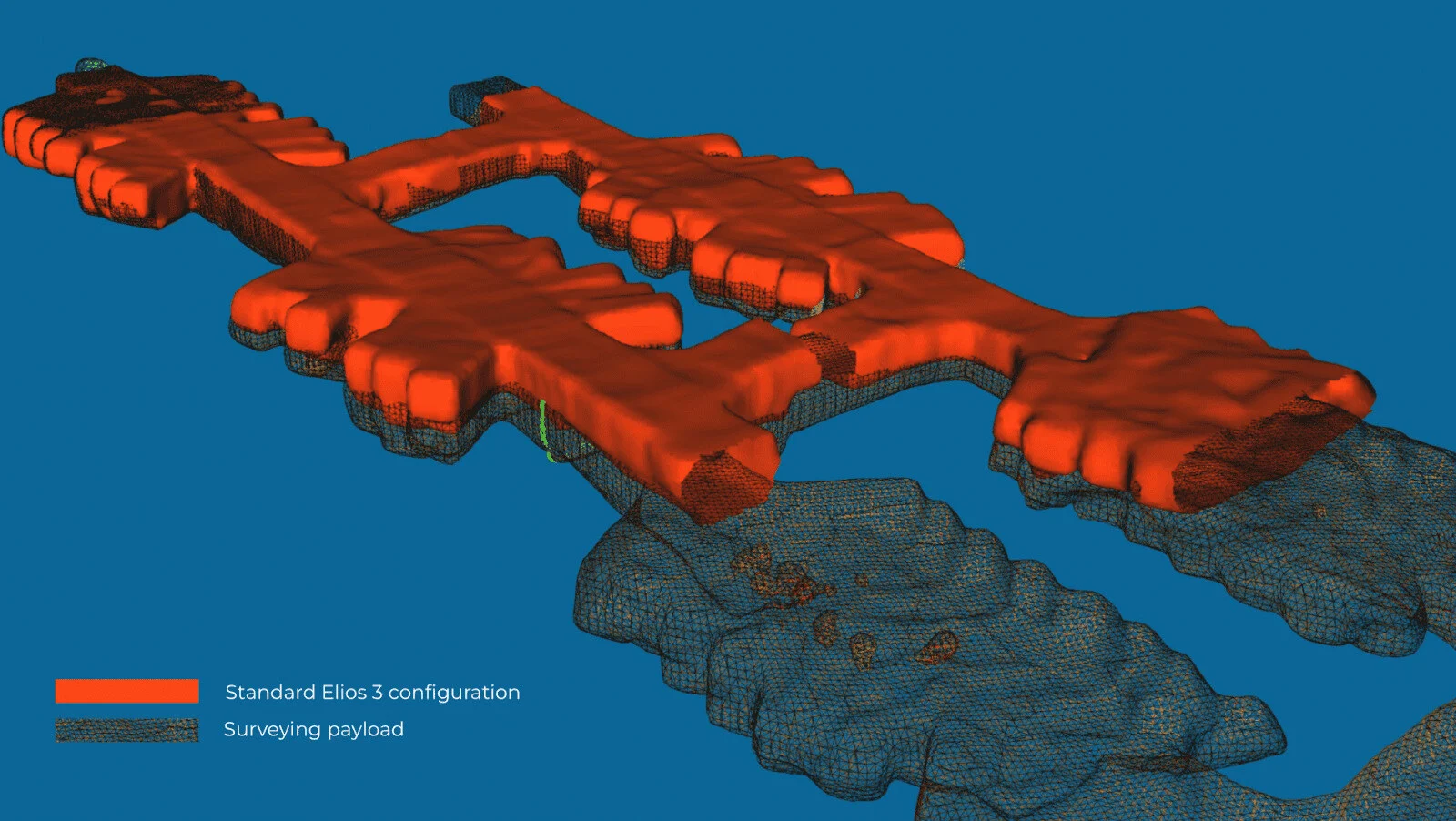

LiDAR surveys inevitably experience some degree of drift, which is the discrepancy between measured and actual locations. While drift occurs across all axes, it's most noticeable in the Z-axis. Drift is typically corrected by referencing known coordinates or control points during post-processing.

With the new surveying payload, Simon observed significant reductions in drift. The Elios 3’s new payload matches the precision of ICL Boulby’s terrestrial laser scanners. Consequently, post-processing time is minimized, enabling ICL to explore more precise applications for the new surveying payload.

Five times more accurate on the z-axis: The red scan shows greater drift with the old payload, while the black scan demonstrates the new Rev 7 LiDAR's improved accuracy, reducing drift by five times.

These enhancements in Z-axis accuracy make the surveying payload suitable for water drainage planning.

New Applications for the Enhanced Payload

Currently, ICL Boulby uses Elios 3 scans for mapping mine workings and measuring indoor stockpile volumes. Past limitations related to drone size and maneuverability prevented scanning larger stockpiles. However, the new surveying payload allows ICL Boulby to scan even larger stockpiles and mine workings.

"The Elios 3 Surveying Payload is a game-changer for our operations. The faster data collection and improved accuracy alone make it worthwhile to switch from the standard sensor to the new one, and we anticipate unlocking new projects with it too," – Simon Pollitt, Chief Surveyor at ICL Boulby

Moreover, the enhanced Z-axis accuracy simplifies large-scale surveys with fewer flights and shorter flight times. This boosts efficiency by allowing surveyors to cover more sites in less time while maintaining accurate records. Overall, the new payload represents an ideal upgrade for ICL Boulby, saving time, cutting costs, and ensuring safer drone inspections.

For more details about the Elios 3 Surveying Payload’s capabilities or to evaluate whether it fits your surveying needs, contact us! Our team of experts is ready to assist you, no matter where you are in your drone adoption journey.

The most accurate surveys with the Elios 3 are achieved using the surveying payload.

Punch Press Machine,Tin Can Making Machine,End Caps Making Machine,Basic Shell Cover Making Machine

Zhoushan Golden Wing Machinery Co., Ltd. , https://www.goldenwingmachines.com