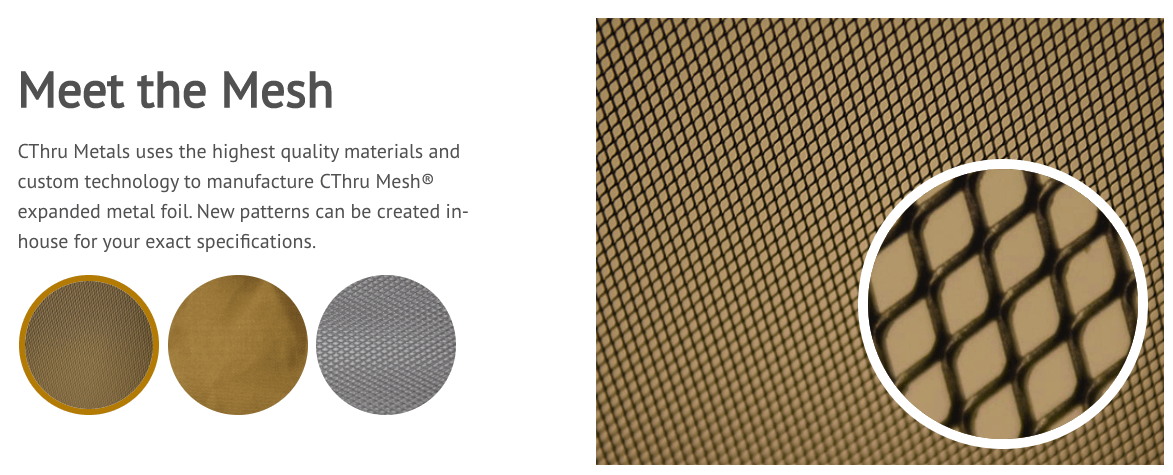

ESI is thrilled to introduce CThru Metals, a brand-new division within our metal forming and manufacturing division. This innovative addition focuses on producing high-quality expanded metal mesh foil with precision, offering thinner gauges, wider coils, and enhanced durability that meet the evolving needs of modern industries.

Why Expanded Metal Mesh Foil?

Expanded metal mesh foil offers a more reliable and efficient alternative to traditional woven wire or perforated metal. Unlike woven wire, which is made from multiple components, expanded metal is formed from a single piece of material, ensuring greater strength, consistency, and less waste during production.

Our engineering team has developed specialized equipment and techniques to create custom expanded metal mesh products tailored to exact specifications. We can produce mesh from a wide range of materials, including stainless steel, copper, aluminum, titanium, and exotic alloys, making us a one-stop solution for diverse applications.

In recent years, expanded metal has gained popularity over perforated metal due to its reduced waste. For instance, if 50% of a sheet is removed in the perforation process, 50% becomes scrap. In contrast, expanded metal minimizes material loss through precise cutting and stretching, making it a more sustainable and cost-effective option.

Our advanced processes allow us to achieve tight tolerances, ensuring consistent quality and performance. Our diamond sizes range from 0.03 to 0.5 inches, with mesh openings ranging from 25 to 5,000 per square inch. We work with metal thicknesses as thin as 0.001†(0.025mm) up to 0.016†(0.40mm), providing flexibility for a wide array of applications.

With the increasing demand for high-performance metal solutions across industries, ESI recognized an opportunity to offer superior expanded metal mesh at competitive prices. CThru Metals provides a full range of services, including:

- – Flattening

- – Stretching

- – Annealing

- – Custom blanking

- – Solid sections

Why Choose CThru Metals?

With over 30 years of experience in metal stamping, ESI has built a strong foundation of expertise that we now apply to expanded metal mesh foil. Our proprietary technology and in-house tooling enable us to deliver custom shapes and sizes for even the most demanding applications.

We specialize in producing expanded metal foil for critical uses such as lightning-strike protection in aircraft and wind turbines, fuel cells, batteries, electronics, solar panels, and EMI shielding for sensitive devices. Additionally, we manufacture custom filters for filtration systems using both metal and plastic mesh.

By handling all stages of production in-house, we ensure faster turnaround times and consistent quality. Whether you need a small batch or large-scale production, our commitment to excellence remains the same.

Over the past three decades, ESI has grown into a trusted name in metal manufacturing. The launch of CThru Metals marks a significant milestone in our journey, allowing us to provide even more advanced and tailored solutions to our industrial clients.

Explore the new CThru Metals website to discover how we can help bring your next project to life with precision, reliability, and innovation.

Polycarboxylate ether water reducer PCE is a new generation high performance and environmental friendly superplasticizer, It can be widely used in premix of common concrete, gushing concrete, hydro concrete, high strength concrete, mass concrete and high quality flow plastic concrete etc.

PCE Liquid is Polycarboxylate Based Superplasticizer, using polyether as main raw material. It has very good slump retention and adaptability to different cement and materials, especially for summer high temperature construction conditions and long-distance concrete

transport project.

PCE Liquid,PCE Chemical Additive,Superplasticizer PCE Liquid,Polycarboxylate Superplasticizer Liquid

Liaoning Kelong Fine Chemical Co.Ltd. , https://www.kelongchemy.com

Comments are closed