Both carbon steel and mild steel possess unique characteristics and benefits that make them suitable for different applications. The following table provides an overview of these two materials, helping you determine which one is better suited for your specific needs.

Contents

- Carbon Steel vs Mild Steel

- What is Mild Steel?

- What is Carbon Steel?

- Types of Carbon Steel

- Composition and Properties of Carbon Steel vs Mild Steel

- Ductility and Weldability of Carbon Steel and Mild Steel

- Corrosion Resistance of Carbon Steel and Mild Steel

- Weight Difference Between Carbon Steel and Mild Steel

- Comparison of Carbon Steel and Mild Steel Properties

- Price Comparison of Carbon Steel vs Mild Steel

- Which is Better: Mild Steel or Carbon Steel?

- Manufacturing Process of Mild Steel and Carbon Steel

- Finishing Processes for Mild Steel and Carbon Steel

- Applications of Carbon Steel and Mild Steel

Carbon Steel vs Mild Steel

| Property | Mild Steel | Carbon Steel |

|---|---|---|

|

|

|

| Carbon Content | 0.05% – 0.25% (Medium to Ultra-High) | Up to 2.1% (Low) |

| Strength | High | Moderate |

| Ductility | Low to Moderate | High |

| Cost | More expensive | Cost-effective |

| Finishing | Smooth finish | Harder to machine and weld |

What is Mild Steel?

| Aspect | Details |

|---|---|

| Definition | Mild Steel is low-carbon carbon steel. |

| Carbon Content | Contains a low percentage of carbon. |

| Alloying Elements | May include manganese, silicon, and trace phosphorus. |

| Strength and Hardness | Strong but relatively soft compared to higher-carbon steels. |

| Common Uses | Used in wires, steel sheets, and building materials. |

| Popularity | Accounts for 85% of U.S. steel products. |

| Properties | Known for strength, ductility, and affordability. |

What is Carbon Steel?

| Aspect | Details |

|---|---|

| Definition | Has carbon as the primary alloying component. |

| Carbon Content | Ranges from 0.05% to 2.0%, sometimes higher. |

| Versatility | Widely used due to adaptability and affordability. |

| Applications | Used in structural components, machinery parts, tools, and industrial equipment. |

| Corrosion | Prone to rust; mitigated with coatings or maintenance. |

Carbon Steel is Stronger, Harder, and More Brittle than Mild Steel

Strength is crucial for materials as it ensures resistance to bending or damage under harsh conditions. Hardness is necessary for withstanding deformation or scratching when subjected to external forces. These properties are typically tested using methods like the Brinell hardness test or Rockwell hardness scale. The table below details how carbon steel excels in these aspects.

Types of Carbon Steel

| Type of Carbon Steel | Carbon Content (%) | Properties | Common Uses |

|---|---|---|---|

| Low | 0.05 to 0.15 | Ductile, flexible | Automotive parts, piping |

| Medium | 0.3 to 0.5 | Balanced ductility and strength | Tanks, pressure vessels |

| High | 0.6 to 1.0 | Very hard | Cutting tools, blades |

| Ultra High | 1.25 to 2.0 | Very hard, brittle | High-quality knives |

Composition and Properties of Carbon Steel vs Mild Steel

| Type of Steel | Elements | Carbon Content | Properties |

|---|---|---|---|

| Carbon Steel | Iron and carbon | Up to 2.1% | Higher carbon content increases strength but makes it more brittle. |

| Mild Steel | Iron and carbon | 0.05% to 0.25% | Lower carbon content makes it more ductile and malleable. |

Mild Steel is Generally More Weldable Due to Lower Carbon Content

Ductility and Weldability of Carbon Steel and Mild Steel

| Aspect | Details |

|---|---|

| Carbon Content | Low |

| Properties | Soft, easily shaped |

| Uses | Construction, welding |

Carbon Steel vs Mild Steel Corrosion

Carbon Steel

| Property | Details |

|---|---|

| Strength and Durability | Higher carbon content increases strength and durability. |

| Ease of Workability | Lower melting point makes it easier to work. |

| Corrosion Susceptibility | More prone to rust and corrosion. |

| Maintenance | Requires regular protective coatings to prevent deterioration. |

Mild Steel

| Property | Details |

|---|---|

| Flexibility | Greater due to lower carbon content. |

| Strength | Less than carbon steel. |

| Corrosion Resistance | Better, but still needs maintenance. |

| Maintenance | Regular upkeep needed in harsh conditions. |

Weight Difference Between Carbon Steel and Mild Steel

| Steel Type | Carbon Content | Range |

|---|---|---|

| Mild Steel | Lower carbon content | 0.05% – 0.25% by weight |

| Carbon Steel | Higher carbon content | 0.05% – 1.70% by weight |

Carbon Steel vs Mild Steel Properties

| Property | Mild Steel | Carbon Steel |

|---|---|---|

| Workability | Easier to work with | Tougher to work with |

| Cost | Cheaper | More expensive |

| Strength | Less strong; suitable for basic structures | Stronger; ideal for heavy machinery and high-pressure applications |

| Welding | Easier to weld | More difficult to weld |

Price Comparison of Carbon Steel vs Mild Steel

| Property | Details |

|---|---|

| Cost | $800 to $1,000 per ton |

| Strength | Stronger |

| Flexibility | Maintains flexibility while being strong |

| Applications | Large projects like skyscrapers and bridges |

| Value | Cost-effective for strength |

Carbon Steel is Up to 20% Stronger Than Mild Steel

The carbon content in steel determines its properties, making it suitable for various applications. Below are the consequences of varying carbon levels that contribute to these differences.

Which is Better: Mild Steel or Carbon Steel?

| Property | Mild Steel | Carbon Steel |

|---|---|---|

| Best For | Low-stress applications | High-strength applications |

| Advantages |

-Easier to fabricate -Lower cost |

-Up to 20% stronger -High hardness |

| Strength | Less strong | Significantly stronger |

| Cost | Lower cost | Higher cost |

| Welding | Easier to weld | More difficult to weld |

Black Mild Steel is More Pliable and Easier to Form

Its excellent malleable and ductile qualities make it easier to form and shape, which is crucial for construction and manufacturing processes. This flexibility simplifies design and application, reducing labor costs and time. Consequently, it appeals to numerous industries.

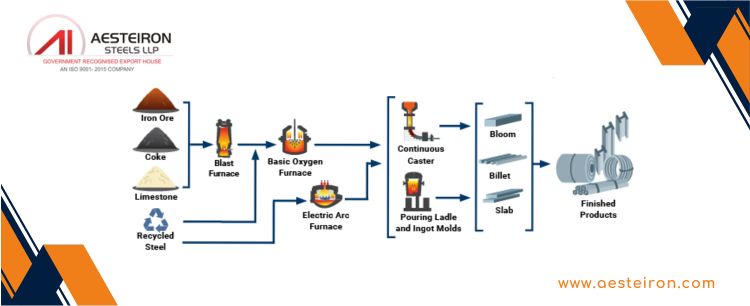

Manufacturing Process of Mild Steel and Carbon Steel

Carbon Steel and Mild Steel are manufactured through three stages:

- Primary processes

- Secondary processes

- Casting processes

Primary Processes

| Aspect | Detail |

|---|---|

| Production Methods | Virgin steel and 100% recycled material or a mix of recycled |

| Process | Basic Oxygen Furnace (BOF) |

| Steel Types | Mild and carbon steel |

| Raw Materials | Iron ore and coke |

| Oxygen Injection | Pure oxygen is used to oxidize excess carbon |

| Carbon Content | Up to 0.5% |

| Casting | Steel is poured into molds to produce slabs or ingots |

Secondary Processes

| Secondary Steelmaking Processes | |

|---|---|

| Purpose: Enhance steel quality and consistency by adjusting carbon content and other characteristics. | |

| Electric Arc Furnace (EAF): | Deoxidizing Steel |

| Importance: In an Electric Arc Furnace, the temperature can be adjusted, certain components can be added or removed, or both. | Importance: Essential for controlling steel properties and suitability for specific applications by eliminating oxygen. |

| – Stirring: Ensures uniform composition by removing non-metallic impurities. | Types of Steel Based on Deoxidation: |

| – Ladle Furnace: Allows accurate control of temperature and addition of alloy components. | – Rimming Steels: Non-deoxidized or partially deoxidized; may produce carbon monoxide. |

| – Ladle Injection: Injects inert gas to stir the steel bath and achieve a homogeneous mixture. | – Capped Steels: Similar to rimming steels but with a capped mold to prevent carbon monoxide formation. |

| – Degassing: Removes unwanted gases (hydrogen, oxygen, nitrogen) and reduces sulfur content. | – Semi-Killed Steels: Moderately deoxidized, with carbon content between 0.15% and 0.3%. |

| – Composition Adjustment: Uses sealed argon bubbling and oxygen blowing (CAS-OB) for precise adjustments. | – Killed Steels: Fully deoxidized to eliminate carbon monoxide during solidification. |

Casting Process

| Traditional Casting Methods | Continuous Casting Methods |

|---|---|

| Pour molten steel into each mold that is set up on a rail vehicle. | Produce molten steel into slabs, blooms, or billets. |

| For hot rolling, ingots are transferred to soaking pits to reheat. | Directly cast steel into shapes more suitable for downstream processing. |

| Uses discrete molds to create individual ingots. | Uses a continuous casting machine for efficient production. |

Mild Steel and Carbon Steel Finishing Processes

Rolling

| Rolling Process | Description |

|---|---|

| Product Rolling | – Rolls solid cast ingots into usable shapes. |

| – Compared to steel, rolls rotate more quickly, propelling and compressing it. | |

| Hot Forming | – Steel heated above recrystallization temperature. |

| – Breaks up as-cast microstructure for uniform grain size and even carbon distribution. | |

| Cold Forming | – Done below recrystallization temperature. |

| – By strain hardening, the strength can be increased by up to 20%. | |

| – Materials that are semi-finished are processed into intermediate products for further use. |

Heat Treatment

| Heat Treatment Process | Temperature Details | Cooling Method | Effects on Steel |

|---|---|---|---|

| Normalizing | Approx. 55 °C (130 °F) | Air-cooling | Increases strength and hardness |

| Annealing | Heated for one hour; cooled at 21 °C (70 °F) | Controlled cooling | Softens and increases ductility |

| Quenching | Much like normalizing | Water, brine, or oil | Very hard but brittle |

| Tempering | Typically between 150-650 °C (300-1200 °F) | Controlled cooling | Reduces brittleness |

Surface Treatment

| Process | Method | Benefits |

|---|---|---|

| Hot Dip Galvanizing | Dipped in molten zinc | Corrosion resistance; weldable |

| Electrolytic Galvanizing | Electric current in zinc solution | Precise coating; corrosion resistance |

Downstream Secondary Processing

- Raw Materials: Steel is processed into finished products by downstream companies.

- Machining: Uniformly removes surface metal using machine tools.

- Joining: Includes welding to combine steel parts.

Mild Steel Widely Used for Low-Stress Applications While Carbon Steel is Used for High-Strength Applications

Below is a detailed table outlining the common applications of both materials.

Applications of Carbon Steel & Mild Steel

| Application | Steel Type | Key Points |

|---|---|---|

| Construction | Mild Steel | Used for building frames, bridges, and structures. |

| Automotive | Carbon Steel | Strong and hard; used for engine parts and chassis. |

| Tools | Carbon Steel | Used for tools like knife drills. |

| Pipes and Pipelines | Carbon Steel | Ideal for strength and corrosion resistance in chemical and gas transport. |

| Cookware | Carbon Steel | Used for pans and knives; provides even heating. |

| Decorative Elements | Mild Steel | Flexible and easy to shape; used for gates, railings, and sculptures. |

| Cost Considerations | Mild Steel | More affordable and easier to obtain. |

| Carbon Steel | More expensive but suitable for long-term use. |

Floor Scrubbing Brush,Floor Washing Machine High Density Filter Element,Short Bristled Antibacterial Roller Brush,Floor Scrubber 0riginal Accessories

Grey Whale Intelligent Appliances (Shenzhen) Co., Ltd , https://www.szgraywhale.com