Testing the Elios 3 Surveying Payload at ICL Boulby Mine

Take a look at how the new Surveying Payload significantly improved surveying efficiency and accuracy at the underground mine ICL Boulby.

Key Advantages

|

Broadened Data Coverage The upgraded LiDAR system in the Elios 3 now offers a longer range, allowing it to cover larger areas more effectively than before. This means higher quality data can be collected in less time. |

Speed With the Surveying Payload, surveying tasks can be completed much faster. At ICL Boulby, a 340-meter tunnel was surveyed in just 10 minutes. |

|

Easier Flight Planning The enhanced LiDAR sensor allows for simpler flight paths. This not only speeds up the surveying process but also cuts down on the number of flights needed, saving both time and energy. |

Precision The new payload boasts five times less drift in LiDAR scans compared to the standard configuration. This leads to more precise data, even in complex environments. |

When Flyability began testing the new Surveying Payload for the Elios 3, they selected a location that frequently used the standard LiDAR data for regular inspections. A team from Flyability visited ICL Boulby to evaluate the new Ouster Rev 7 LiDAR payload against existing maps and determine how the results compared.

Utilizing the Elios 3 at the World's Sole Polyhalite Mine, ICL Boulby

ICL Boulby stands as the only polyhalite mine globally, located just north of Whitby in Northeast England. Initially established for potash mining in 1968, it has since transitioned to mining polyhalite, a type of organic fertilizer.

Operating as deep as 1,200 meters below ground level, the mine stretches under the North Sea, extending up to 12 kilometers (8 miles) offshore. The mine's vastness and historical nature present significant challenges, particularly concerning the numerous old workings alongside ongoing excavations. These must be meticulously documented to prevent accidents like water or gas inflows when accessing older sections. Maintaining accurate records of mine workings is mandatory in the UK.

Simon Pollitt from ICL Boulby suggested employing the Elios 3 to map mine workings as part of regulatory compliance. The mine employs an advance-and-retreat mining strategy, where tunnels are supported ahead and cleared upon retreat. Areas that have been retreated become NoGo zones for personnel. The Elios 3 allows ICL to utilize this mining approach while adhering to regulations. As of 2023, the Elios 3 has been operational at ICL Boulby for nine months, with the surveying team relying heavily on its regular LiDAR scans for various surveying and volumetric projects.

Halving Drone Flight Times with the New Surveying Payload

The specific tunnel measured 340 meters in length and typically required four flights with the Elios 3 to fully capture the area, taking around 20 minutes in total. This involved scanning beyond the drone's visual line of sight, complicating communication between the drone and the remote controller. Post-flight, the scans were registered and processed to create a new point cloud.

However, the introduction of the new LiDAR scanner made a substantial impact.

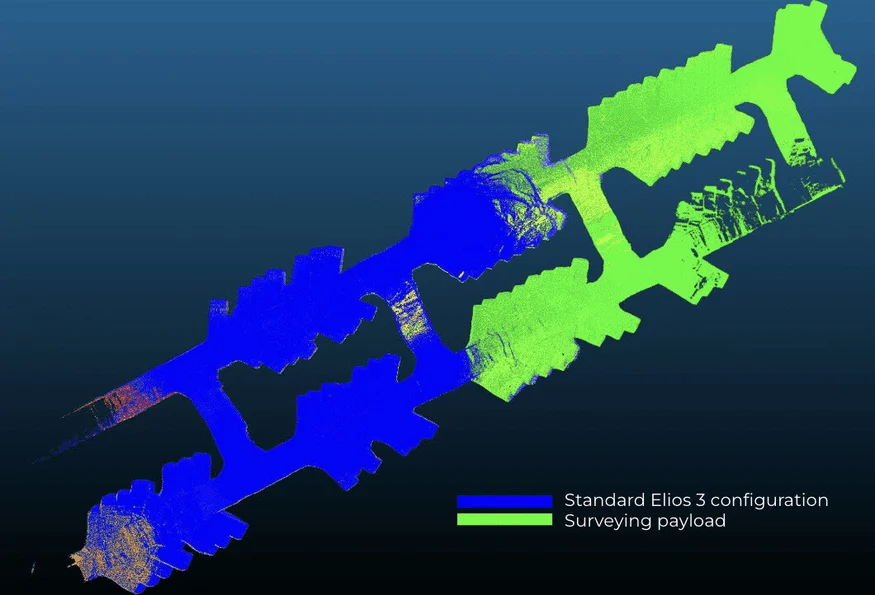

Double the coverage: An overlay of the flights with the two LiDAR configurations reveals twice the coverage with the Surveying Payload.

The new Surveying Payload features an enhanced LiDAR sensor, now the Ouster LiDAR OS0-128 Rev 7. This update brings several key benefits. The Rev 7 offers superior accuracy in positioning and scanning, along with better performance in symmetrical environments. Additionally, it boasts a greater range, enabling scans beyond safe access areas and gathering more data than previously possible. The resulting denser, richer point clouds can be captured more efficiently and processed using the payload's integrated software, FARO Connect, which automatically produces clean georeferenced point clouds from the Elios 3's new payload data.

VIDEO: Fly-through of the data captured in one flight by the Elios 3 Surveying Payload

With the new surveying payload, Simon managed to complete one scan covering the entire area previously surveyed, halving the flight time and conserving battery power. Moreover, due to the extended range, post-processing time was halved as there was no need to merge multiple scans.

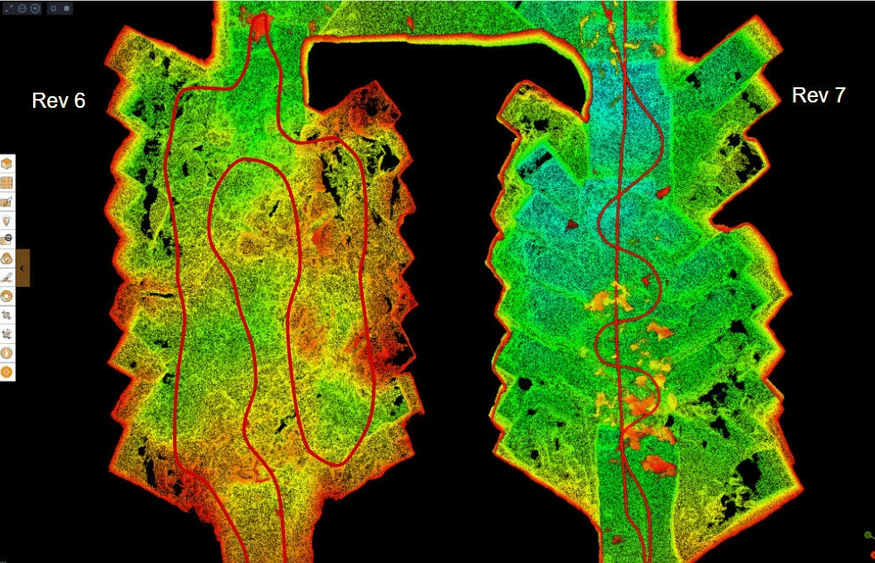

Simplified flight trajectory for similar outcomes: The left image shows the trajectory of the original survey payload, while the right image illustrates the new surveying payload.

Aligning Terrestrial Scans with Enhanced Drift and Z-Values

During LiDAR-based surveys, some degree of drift is expected. Drift refers to the discrepancy between the measured location and the actual location, occurring across all axes but most notably in the Z-axis. Drift is corrected by scanning known coordinates or points, called control points, to georeference the scan.

With the new surveying payload, Simon noticed a marked improvement in reducing drift. The expanded scale and range of the Elios 3’s new surveying payload align closely with ICL Boulby’s terrestrial laser scanners. This reduces post-processing time and enables ICL to explore new applications requiring higher precision.

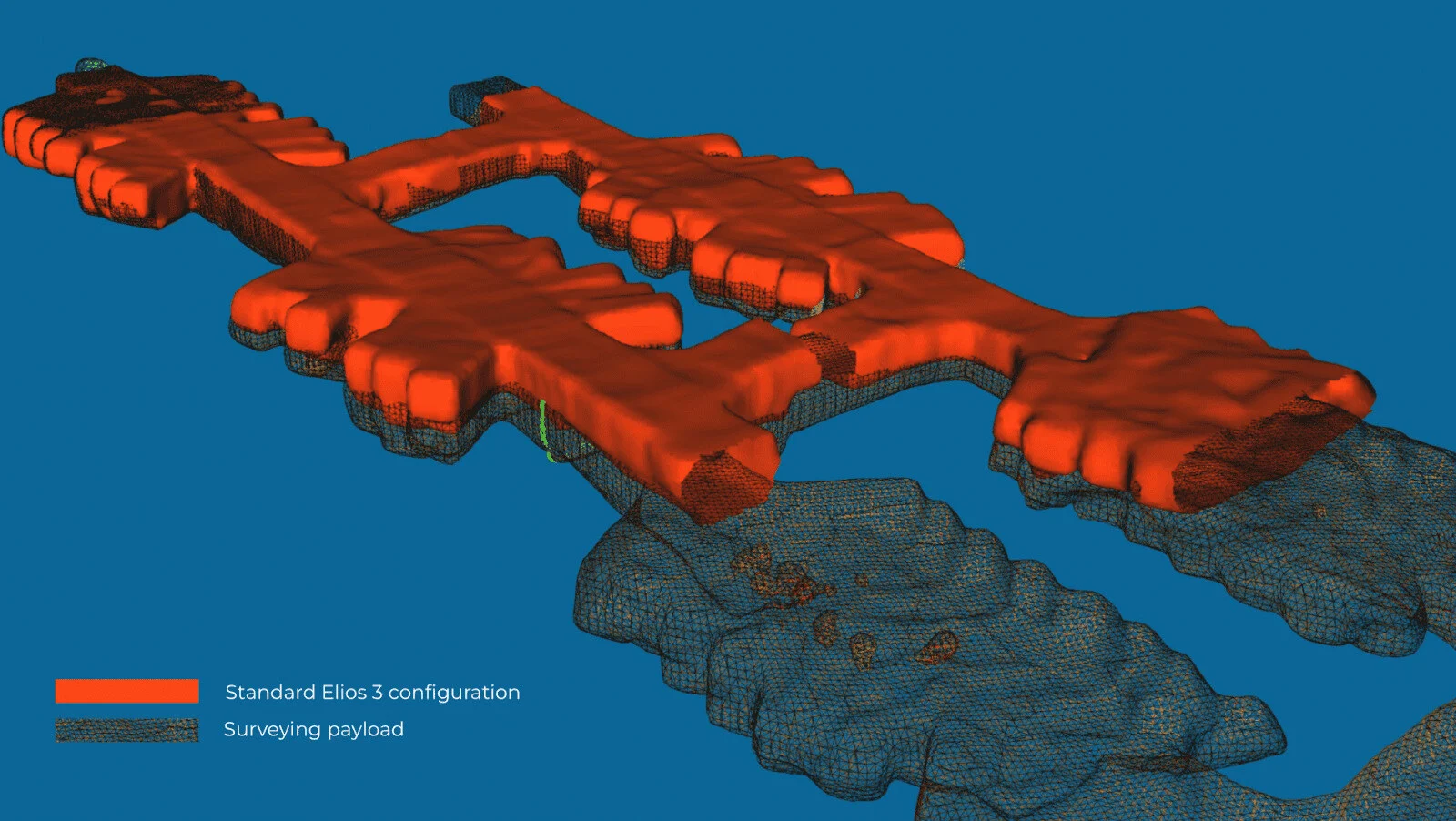

Nearly 5x more precise on the z-axis: The red represents a scan taken with the old payload showing greater drift compared to the black scan with the new Rev7 LiDAR. The accuracy improvement in this case was a 5x reduction in drift.

The advancements in Z-axis accuracy mean the surveying payload will be employed for water drainage planning.

Expanding Use Cases with the New Payload

Currently, ICL Boulby uses Elios 3 scans for mapping mine workings and measuring indoor stockpile volumes. Previously, limitations existed regarding drone usage for stockpile surveys due to size and maneuverability. With the new surveying payload, ICL Boulby anticipates scanning further into indoor stockpiles and mine workings.

"The Elios 3 Surveying Payload is a game-changer for our operations. The faster data collection and increased accuracy alone make it worthwhile switching from the standard sensor to the new one, and we're excited about the potential to unlock new projects with it too," – Simon Pollitt, Chief Surveyor at ICL Boulby

In addition, the enhanced accuracy regarding the Z-axis will facilitate large-scale surveys with fewer flights and shorter flight times. This helps surveyors reduce work per survey and cover more sites in less time, boosting efficiency while maintaining accurate records. Overall, the new payload presents an ideal upgrade for ICL Boulby and Simon’s team, helping save time, cut costs, and ensure safety during drone inspections.

For more information on the capabilities of the Elios 3 Surveying Payload or to evaluate its suitability for your surveying needs, feel free to reach out to us! Our team of specialists is available to assist you, regardless of your stage in adopting drone technology.

The most accurate surveys with the Elios 3 are completed with the surveying payload.

Seam Welding Machine,Can Welding Machine,Tin Can Welding Machine,Tin Can Seam Welding Machine

Zhoushan Golden Wing Machinery Co., Ltd. , https://www.goldenwingmachines.com