Table of contents

- What is 45 Degree Elbow?

- Advantages of Using 45 Degree Elbows in Construction and Infrastructure Projects

- 45 Degree Elbow Dimensions

- 45 Degree Street Elbow Weight Chart

- 3 Inch 45-Degree Elbow Materials and Grades

- How to Calculate 45 Degree Elbow Center

- 45 Degree Angle Elbow Pressure Rating

- How to Calculate 45 Degree Elbow Length

- Features of 45 Degree Stainless Steel Elbow

- Disadvantages of 45 Degree Pipe Elbow

- Applications of 45 Degree Long Radius Pipe Elbow

What is a 45 Degree Elbow?

A 45-degree elbow is a type of pipe fitting used to change the direction of a piping system by 45 degrees. It helps maintain smooth flow, reduce turbulence, and minimize pressure loss, which can improve the overall efficiency of the system.

Discover the Benefits of Using 45-Degree Elbows in Construction and Infrastructure

Advantages of Using 45 Degree Elbows in Construction and Infrastructure Projects

- Versatile and widely applicable

- Easy to install and integrate into existing systems

- Improves water or fluid flow efficiency

- Cost-effective compared to other fittings

- Enhances the visual appeal of installations

- Reduces energy consumption due to improved flow

- Minimizes pressure drop across the system

- Ensures smooth and uninterrupted fluid movement

- Helps prevent erosion in high-flow areas

- Boosts system performance and longevity

Understand the Sizes and Dimensions of 45 Degree Pipe Elbows

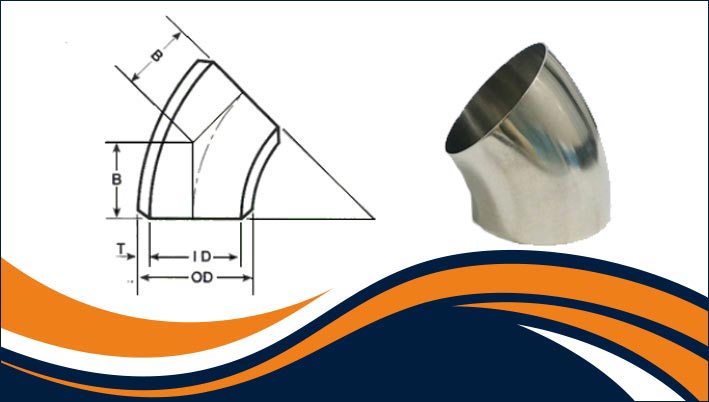

The size and dimensions of a 45-degree pipe elbow are crucial for ensuring a secure and leak-free connection within the piping system. Choosing the right size that matches the pipe diameter is essential to avoid inefficiencies, structural issues, or failures.

45 Degree Elbow Dimensions

| NPS | OD at Bevel | Center to End |

|---|---|---|

| 45 degree B | ||

| 1/2 | 21.3 | 15.7 |

| 1 | 33.4 | 22.4 |

| 1-1/2 | 48.3 | 28.4 |

| 2 | 60.3 | 35.1 |

| 3 | 88.9 | 50.8 |

| 4 | 114.3 | 63.5 |

| 6 | 168.3 | 95.2 |

| 10 | 273.1 | 158.8 |

| 14 | 355.6 | 222.2 |

| 18 | 457.2 | 285.8 |

| 22 | 558.8 | 342.9 |

| 26 | 660.4 | 406.4 |

| 30 | 762 | 469.9 |

| 34 | 863.6 | 533.4 |

| 38 | 965.2 | 599.9 |

| 42 | 1066.8 | 660.4 |

| 46 | 1168.4 | 726.9 |

| 52 | 1320.8 | – |

| 56 | 1422.4 | 883.8 |

| 66 | 1676.4 | 1041.6 |

| 72 | 1829 | 1137 |

| 80 | 2032 | 1263 |

Review the Weight Chart of 45 Degree Long Radius Pipe Elbows

Knowing the weight of a 45-degree long radius elbow is important for safe handling and installation. It also plays a key role in estimating the total cost of the piping system and ensuring proper load distribution during installation.

45 Degree Street Elbow Weight Chart

| NPS in inch | Sched XXS in kilogram |

Sched 160 in kilogram |

Sched XS in kilogram |

Sched STD in kilogram |

|---|---|---|---|---|

| 1/2 | Â | Â | Â | .04 |

| 3/4 | .08 | Â | .07 | .04 |

| 1 | .18 | .17 | .13 | .11 |

| 1 1/4 | .25 | .23 | .20 | .15 |

| 1 1/2 | .52 | .35 | .27 | .21 |

| 2 | .96 | .79 | .47 | .35 |

| 2 1/2 | 1.7 | 1.35 | .86 | .75 |

| 3 | 2.6 | 2.0 | 1.39 | 1.01 |

| 3 1/2 | 3.9 | Â | 2.14 | 1.42 |

| 4 | 4.8 | 4.3 | 2.65 | 1.91 |

| 5 | 8.6 | 7.65 | 4.65 | 3.26 |

| 6 | 14.4 | 13.5 | 7.5 | 5.18 |

| 8 | 27 | 29 | 15 | 10 |

| 10 | Â | 61 | 24 | 18 |

| 12 | Â | 104 | 33 | 27 |

| 14 | Â | 125 | 43 | 33 |

| 16 | Â | 187 | 59 | 46 |

| 18 | Â | Â | 77 | 57 |

| 20 | Â | Â | 92 | 70 |

| 24 | Â | Â | 133 | 100 |

| 26 | Â | Â | 164 | 124 |

| 30 | Â | Â | 214 | 165 |

| 36 | Â | Â | 318 | 239 |

| 42 | Â | Â | 428 | 320 |

45 Degree Elbows Are Available in Various Materials Like Stainless Steel, Carbon Steel, and Nickel Alloys

Each material has unique properties that make it suitable for different applications. The following table lists the materials, standards, and grades commonly used for 45-degree elbows to help you choose the best option for your project.

3 Inch 45-Degree Elbow Materials and Grades

| Material | Standards and Grade |

|---|---|

| Carbon Steel |

|

| Incoloy |

|

| Stainless Steel |

|

| Copper Nickel |

|

| Alloy Steel |

|

| Titanium |

|

| Inconel |

|

| Hastelloy |

|

| Super Duplex |

|

| Nickel Alloy |

|

| Aluminum |

|

| Duplex |

|

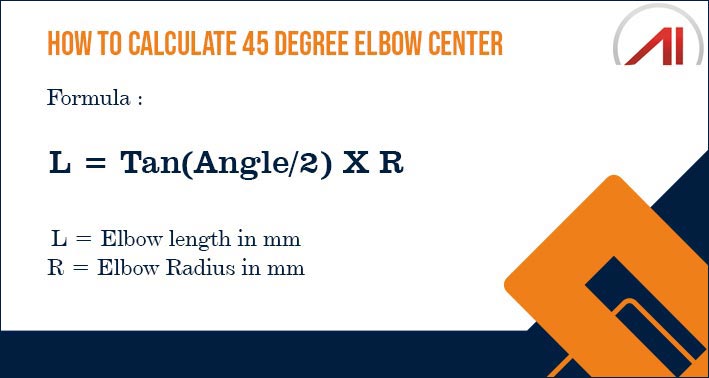

How to Calculate 45 Degree Elbow Center

45 Degree Angle Elbow Pressure Rating

| Temperature | Class (lbs) | ||||

|---|---|---|---|---|---|

| 150 | 300 | ||||

| oC | oF | 2 1/2 – 3 inch. | 1 1/4 – 2 inch. | 1/4 – 1 inch. | |

| -29 to 66 | -20 to 150 | 300 | 1000 | 1500 | 2000 |

| 93 | 200 | 265 | 910 | 1350 | 1785 |

| 121 | 250 | 225 | 825 | 1200 | 1575 |

| 149 | 300 | 185 | 735 | 1050 | 1360 |

| 177 | 350 | 150 | 650 | 900 | 1150 |

| 204 | 400 | – | 560 | 750 | 935 |

| 232 | 450 | – | 475 | 600 | 725 |

| 260 | 500 | – | 385 | 450 | 510 |

| 288 | 550 | – | 300 | 300 | 300 |

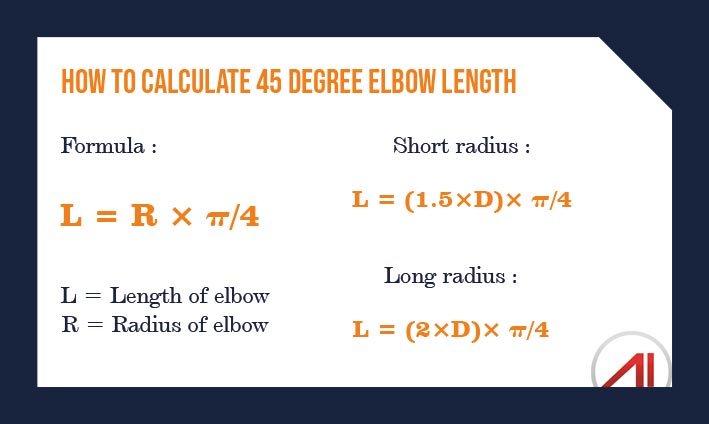

How to Calculate 45 Degree Elbow Length

45 Degree Black Elbows Are Manufactured According to ASME B16.9 Standards

ASME B16.9 is an industry standard for butt-weld fittings, established by the American Society of Mechanical Engineers. It covers various aspects such as sizes, tolerances, pressure ratings, materials, surface finish, and testing procedures for these fittings.

Features of 45 Degree Stainless Steel Elbow

- Smooth interior surface for optimal flow

- Designed to handle mechanical stress and high pressure

- High durability and long service life

- Excellent performance in harsh environments

- Easy to install and maintain

- Resistant to extreme temperatures

Disadvantages of 45 Degree Pipe Elbow

- Can cause some pressure loss

- May disrupt the flow slightly

- Requires more space for installation

- More expensive than straight pipe sections

- Needs regular maintenance over time

- Not ideal for very sharp turns

- Increases friction in the system

Applications of 45 Degree Long Radius Pipe Elbow

- Water supply systems

- Chemical and industrial pipelines

- Food processing and beverage lines

- Air conditioning and HVAC systems

- Electronic manufacturing facilities

- Solar energy installations

- Agricultural irrigation systems

- Drainage and waste management

- Gas distribution networks

- Power generation systems

Donaldson is a renowned global leader in filtration solutions for a wide range of industries, offering innovative products that enhance performance, reliability, and efficiency. Founded in 1915 and headquartered in Bloomington, Minnesota, USA, Donaldson serves customers worldwide with a diverse portfolio of filtration solutions designed to meet the stringent demands of various applications.

Categories of Donaldson Products

-

Air Filtration:

- Industrial Air Filters: Donaldson manufactures a comprehensive range of industrial air filters designed to remove contaminants such as dust, dirt, and particulates from air intake systems. These filters are crucial for protecting equipment, improving air quality, and enhancing operational efficiency in manufacturing plants, power generation facilities, and industrial environments.

- Engine Air Filters: Engine air filters play a critical role in maintaining the performance and longevity of engines by preventing harmful contaminants from entering combustion chambers. Donaldson offers a variety of engine air filters for automotive, heavy-duty trucking, construction equipment, and Agricultural Machinery applications.

-

Liquid Filtration:

- Hydraulic Filtration: Donaldson hydraulic filters are designed to protect hydraulic systems from contaminants that can cause equipment failure and downtime. These filters ensure clean hydraulic fluid, thereby optimizing equipment performance and extending component life in construction, mining, and industrial machinery.

- Fuel Filtration: Fuel filters from Donaldson remove water, particulates, and other contaminants from fuel systems, enhancing fuel quality and reliability in diesel engines used in transportation, agriculture, marine, and stationary power applications.

-

Process Filtration:

- Industrial Process Filters: Donaldson offers a range of process filters for applications in pharmaceuticals, food and beverage, electronics, and chemical industries. These filters ensure product quality, regulatory compliance, and operational efficiency by removing impurities and maintaining clean process fluids.

- Compressed Air and Gas Filtration: Compressed air and gas filters play a crucial role in maintaining the quality and reliability of compressed air systems. Donaldson's filters remove moisture, oil, and contaminants, ensuring clean and dry air for various industrial processes and applications.

-

Exhaust and Emissions Solutions:

- Exhaust Gas Filtration: Donaldson develops advanced exhaust gas filtration solutions to reduce emissions of particulate matter and harmful gases from diesel engines and industrial processes. These solutions help meet stringent environmental regulations and improve air quality in urban areas and industrial facilities.

- Catalysts and Aftertreatment Systems: Donaldson offers catalysts and aftertreatment systems that complement exhaust gas filtration, enabling efficient reduction of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate emissions from diesel engines and industrial sources.

-

Industrial Filtration Systems:

- Dust Collection Systems: Donaldson manufactures dust collectors and filtration systems for capturing and controlling airborne dust and particulates in industrial environments. These systems improve air quality, protect workers' health, and comply with regulatory standards in industries such as metalworking, mining, woodworking, and pharmaceutical manufacturing.

- Mist Collection Systems: Donaldson's mist collectors are designed to remove oil mist, coolant mist, and other aerosols from machining operations, ensuring clean air and maintaining equipment performance and longevity in automotive, aerospace, and metal fabrication industries.

Â

We offer a complete line of fuel filters for mainstream on-highway and off-highway applications.Spin-on and cartridge filters in a wide variety of filter media

Donaldson,Donaldson Hydraulic Oil Filters,Donaldson Hydraulic Filters,Donaldson Hydraulic Filter Cartridge

Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com